How To Configure The Out-of-Stock Threshold In Magento 2?

Are you struggling to manage product availability in your Magento store? The out-of-stock threshold Magento 2 feature helps you streamline inventory management automatically.

This tutorial will cover how to set up and use the out-of-stock threshold in Magento 2.

Key Takeaways

-

Notify customers and ensure accurate stock status with backorders enabled on your storefront.

-

Manage inventory by automatically marking products out of stock when the quantity reaches a specific limit.

-

Enable backorders to allow the purchase of products even when the stock is below zero.

-

Improve the efficiency of stock control with features of Magento 2 out-of-stock option.

-

Configure the out-of-stock threshold, enable backorders, and handle notifications.

-

Advanced settings and best practices for enhancing your storefront and sales process.

-

What Is The Out-Of-Stock-Threshold In Magento 2 Stock Management?

-

5 Steps To Configure Default Inventory Settings For a Particular Product Stock Option

-

2 Methods To Configure Advanced Inventory Settings For Out-Of-Stock Threshold Option

-

Troubleshooting Common Issues With Stock When Order Is Cancelled

What Is The Out-Of-Stock-Threshold In Magento 2 Stock Management?

The out of stock threshold in Magento 2 allows you to set a minimum quantity of a product that must be in stock before it is considered available for purchase.

If the quantity of a product falls below this threshold, it will be considered out of stock. Customers will not be able to purchase it then. Setting a minimum quantity of a product that must be in stock can avoid overselling. It ensures that you always have enough stock to meet customer demand. If a product is out of stock, customers will not be able to purchase it. It can reduce frustration and improve customer satisfaction. The out-of-stock threshold can help you manage your stock more effectively.

For instance, if you set a minimum stock of "20" for a product that sells "5 units" daily, you have a "4-day buffer" to restock. It reduces the risk of stockouts while maintaining efficient inventory turnover.

Follow the steps below to determine the stock level:

- Log in to your Magento 2 admin panel and navigate to the product page.

- Click on the “Inventory” tab and select “Manage Stock”.

- Set the “Out of Stock Threshold” to the desired quantity.

- Enter a number in the "Out of Stock Threshold" field. This number represents the stock level at which a product will be marked as out of stock.

For example, if you enter "-5," the product will remain in stock until the quantity drops below -5.

- Save your changes.

- Your storefront will now display products as out of stock once they reach the defined threshold.

For example, a clothing retailer might set higher thresholds for winter coats in autumn. He can lower them in spring and adjust them based on weather forecasts and historical sales data.

4 Steps To Configure Default Magento Inventory Settings

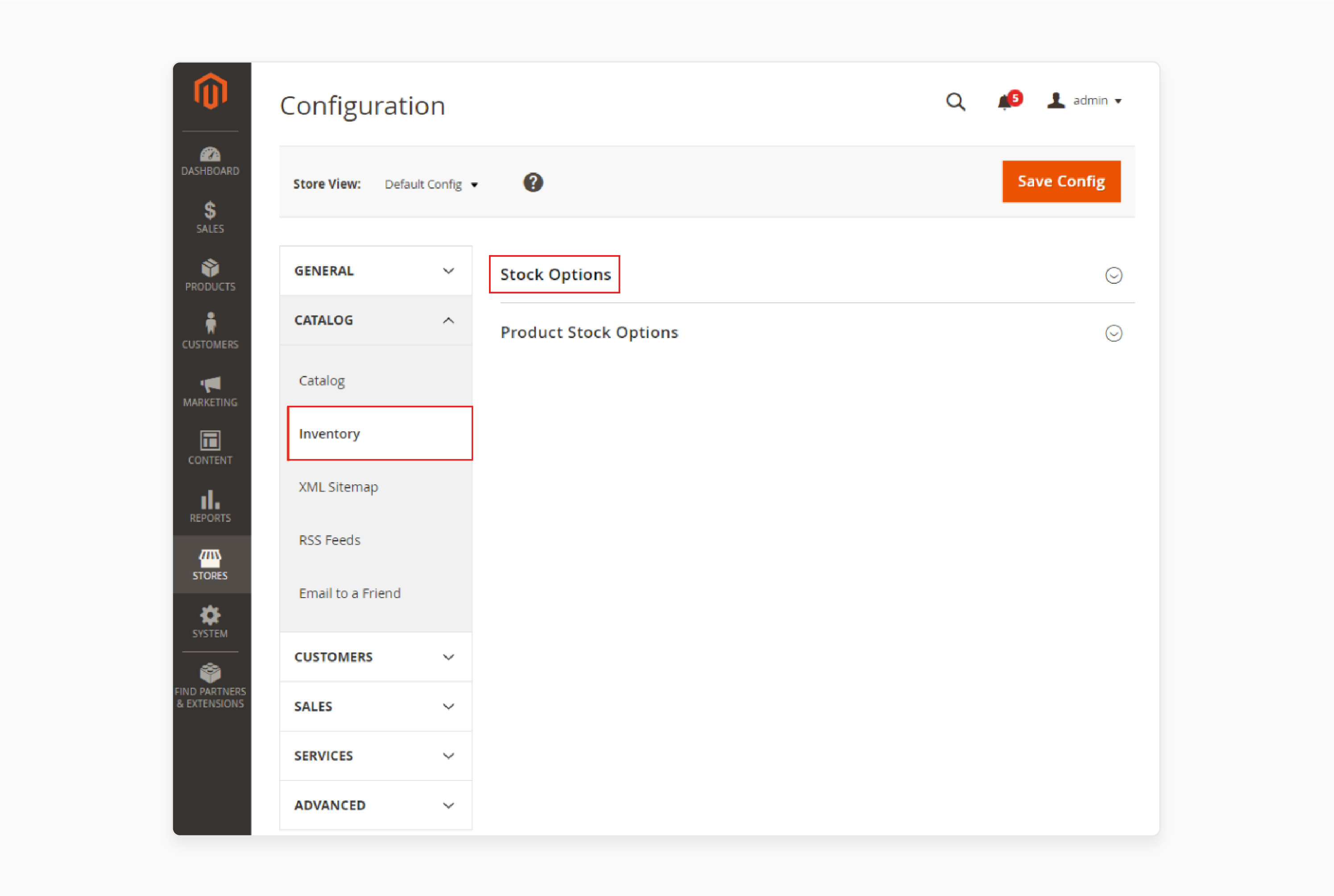

- Log in to the Magento Admin Panel.

- Navigate to Stores > Configuration > Catalog > Inventory.

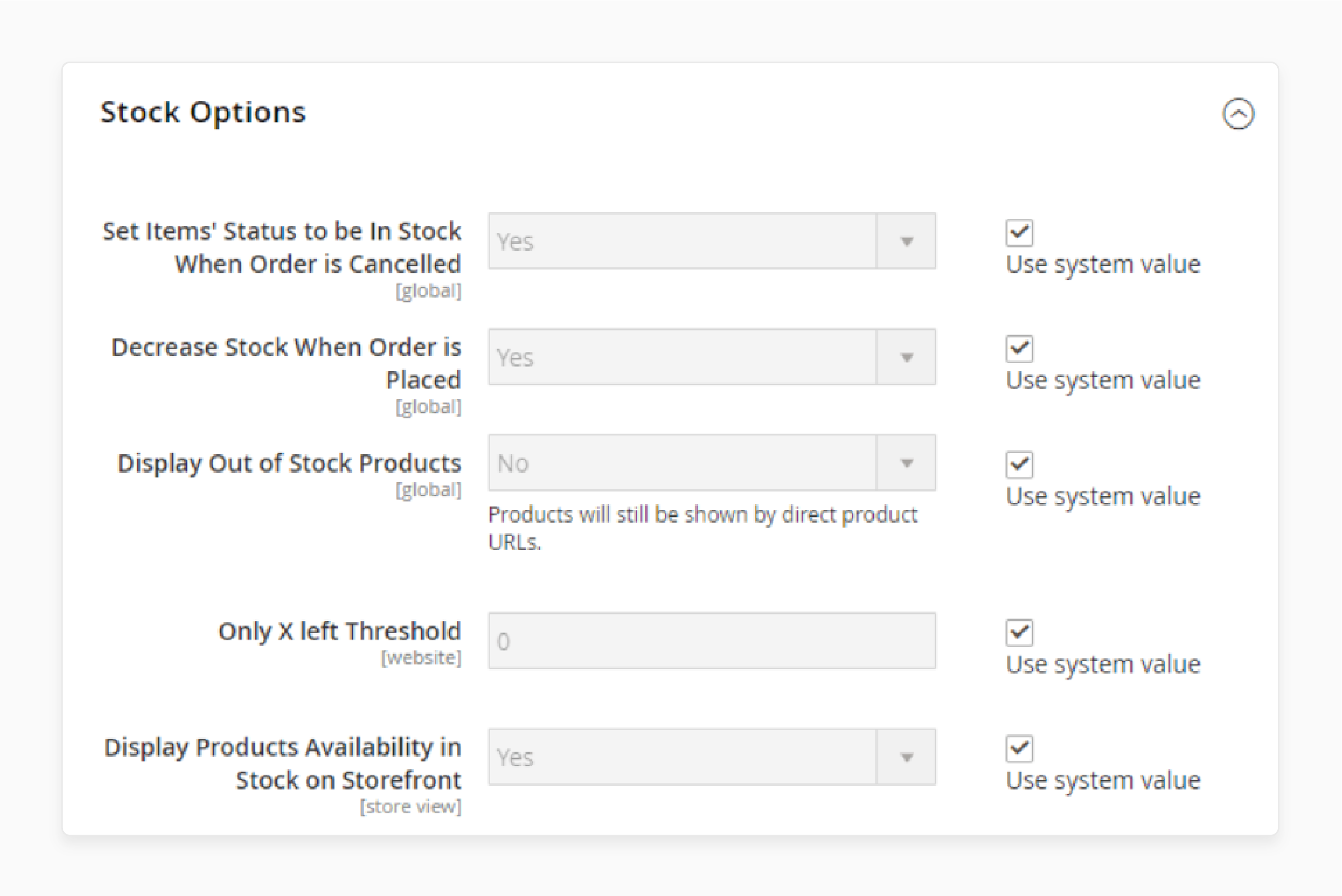

- Extend the 'Stock Options' drop-down menu to configure the following:

-

Decrease Stock When Order is Placed: Choose "Yes" to automatically reduce stock when an order is placed.

-

Set Items' Status to be In Stock When Order is Placed: Select "Yes" if you want items from canceled orders to be restocked.

-

Display Out of Stock Products: Set to "Yes" if you want out-of-stock products to be visible in your Magento 2 store.

-

Only X left Threshold: Input the number of items to display on the product page, regardless of the actual stock level.

-

Display Products Availability in Stock on Storefront: Enable this to show the actual number of products remaining in stock.

-

Enable Inventory Check On Cart Load: It determines whether an inventory check is performed when adding a product to the cart. Disabling this check can improve checkout performance, especially with large carts.

-

Synchronize with Catalog (Global): When enabled, this setting ensures that inventory data is automatically updated. It reflects changes in the catalog. Examples include product removals, SKU updates, and product type modifications. It maintains consistency between the inventory and catalog.

Note: However, skipping pre-validation may result in customers encountering out-of-stock errors later in the checkout process.

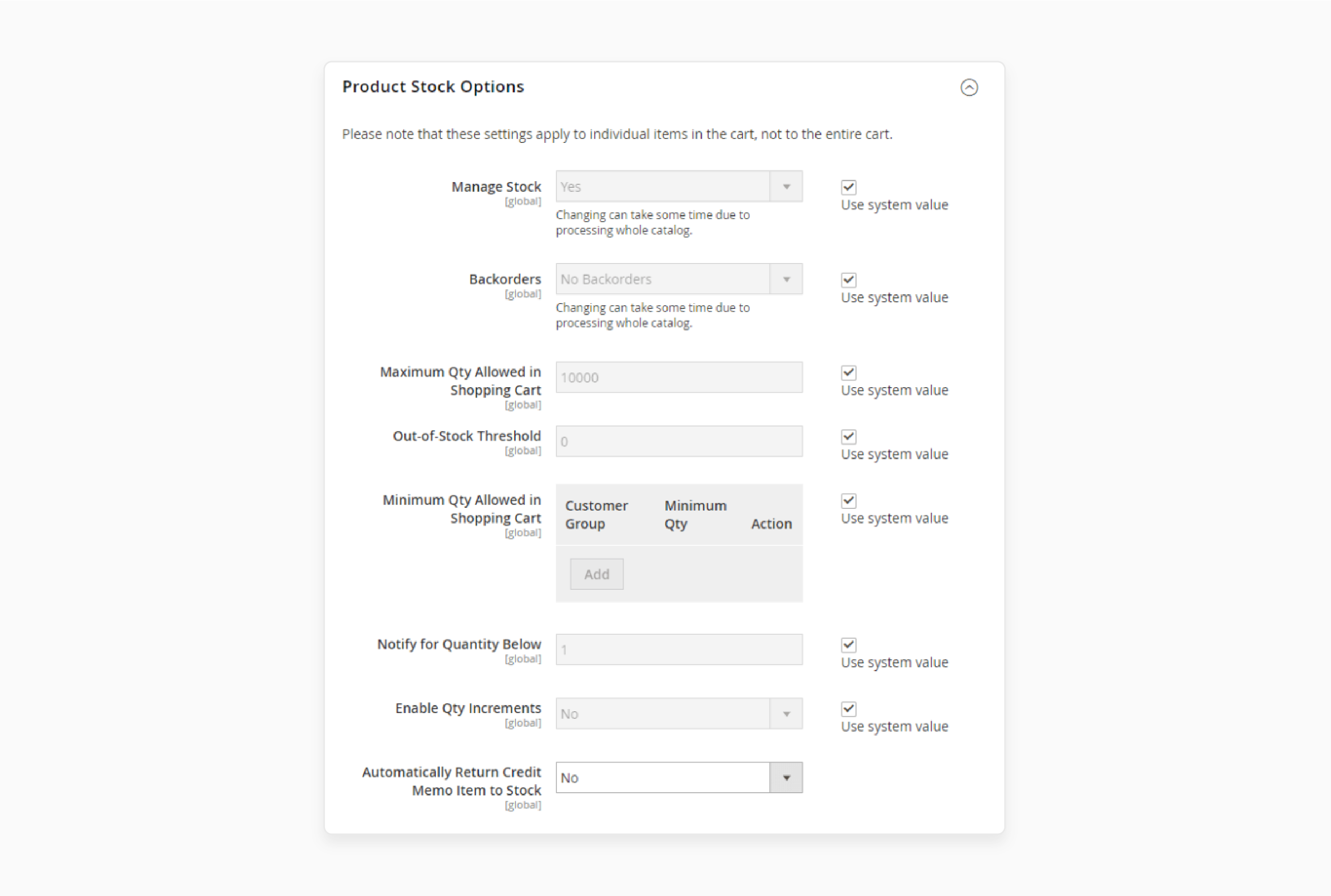

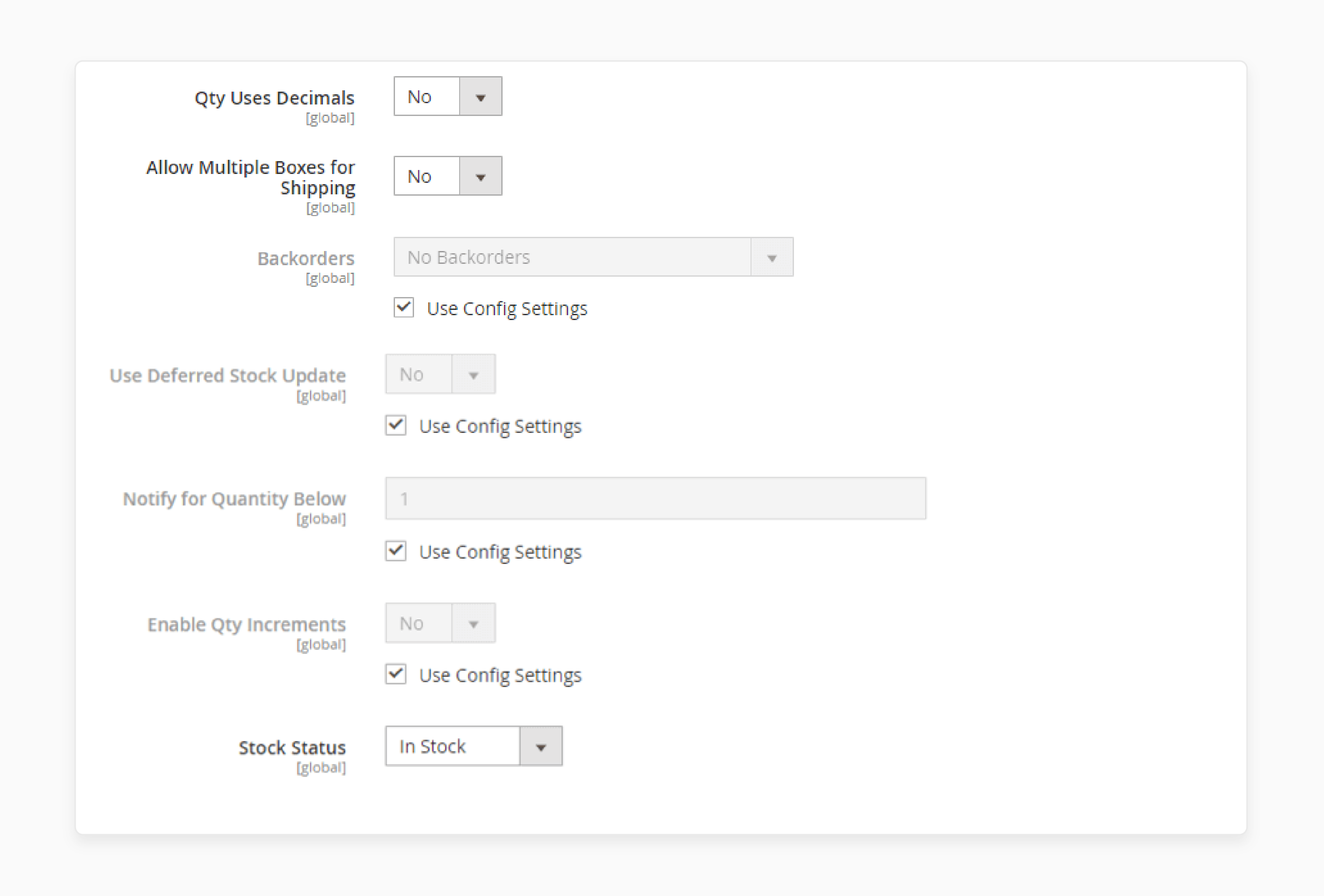

- Switch to the 'Product Stock Options' menu to adjust additional settings:

-

Manage Stock: This is enabled by default. If you sell virtual products, you can disable this option.

-

Backorders: To allow customers to order out-of-stock items, select ‘Allow Qty Below 0 and Notify Customer’. Or ‘Allow Qty Below 0’ if you're willing to fulfill orders once stock is replenished.

-

Maximum Qty Allowed in Shopping Cart: Set the maximum number of items allowed in a single cart.

-

Out-of-Stock Threshold: Define the stock level at which products are displayed as out of stock on the product page.

-

Minimum Qty Allowed in Shopping Cart: Set the minimum number of items required for purchase.

-

Notify for Quantity Below: Set the stock level that triggers a notification when inventory is running low.

-

Enable Qty Increments: Specify the quantity increments for stock replenishment.

-

Automatically Return Credit Memo Item to Stock: Enable this option to restock items from returned or canceled orders automatically.

5 Steps To Configure Default Inventory Settings For a Particular Product Stock Option

-

Navigate to Products > Catalog.

-

Select the product you want to configure.

-

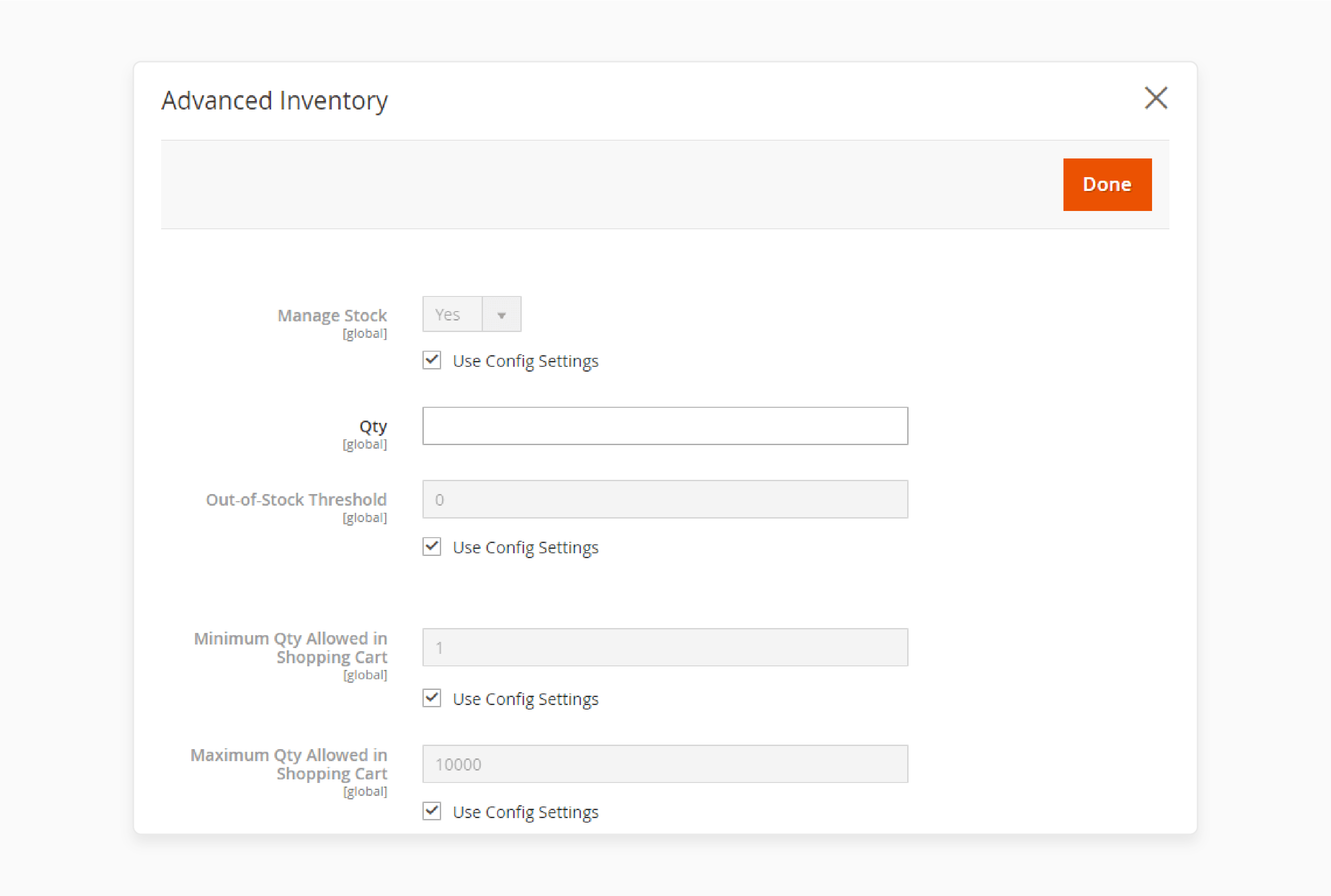

Click on 'Advanced Inventory'.

Note: Here, you can make all the necessary adjustments. If you enable the 'Allow Multiple Boxes for Shipping' option, different parts of the same product can be shipped separately. If you need to update the product quantity quickly, you can do so in the Product Details section.

-

Save your changes.

-

Clear the Magento cache after completing the settings.

Best Practices For Managing Products In Stock

| Best Practices | Description |

|---|---|

| Audit Your Inventory Regularly | - Conduct frequent inventory audits. - Ensure accuracy in stock levels and identify discrepancies early. - Maintain an accurate count of products in stock. |

| Implement FIFO (First In, First Out) | - Use the FIFO method to ensure older stock is sold first. It reduces the risk of obsolescence and spoilage. - Manage products in stock effectively. |

| Set Minimum Stock Levels | - Determine minimum stock levels to avoid stockouts. - Ensure you always have enough products in stock to meet customer demand. |

| Utilize Inventory Management Software | - Leverage inventory management systems to track product movements. - Automate stock level updates to improve efficiency in managing products in stock. |

| Maintain Healthy Supplier Relationships | - Build strong relationships with suppliers to ensure timely restocking of products in stock. - Avoid supply chain disruptions. |

| Forecast Demand Accurately | - Use demand forecasting tools to predict future inventory needs. - Ensure optimal levels of products in stock without overstocking. |

| Optimize Warehouse Operations | - Streamline warehouse processes to improve the storage & retrieval of products in stock. - Enhance order fulfillment speed and accuracy. |

| Plan for Peak Seasons | - Prepare for peak demand periods by increasing inventory levels and staffing. - Ensure sufficient products are in stock to handle increased sales volume. |

| Monitor Inventory Data Continuously | - Regularly analyze inventory data to identify trends. - Adjust stock levels accordingly, maintaining a balanced inventory. |

2 Methods To Configure Advanced Inventory Settings For Out-Of-Stock Threshold Option

There are 2 methods to enhance the default Magento stock management capabilities.

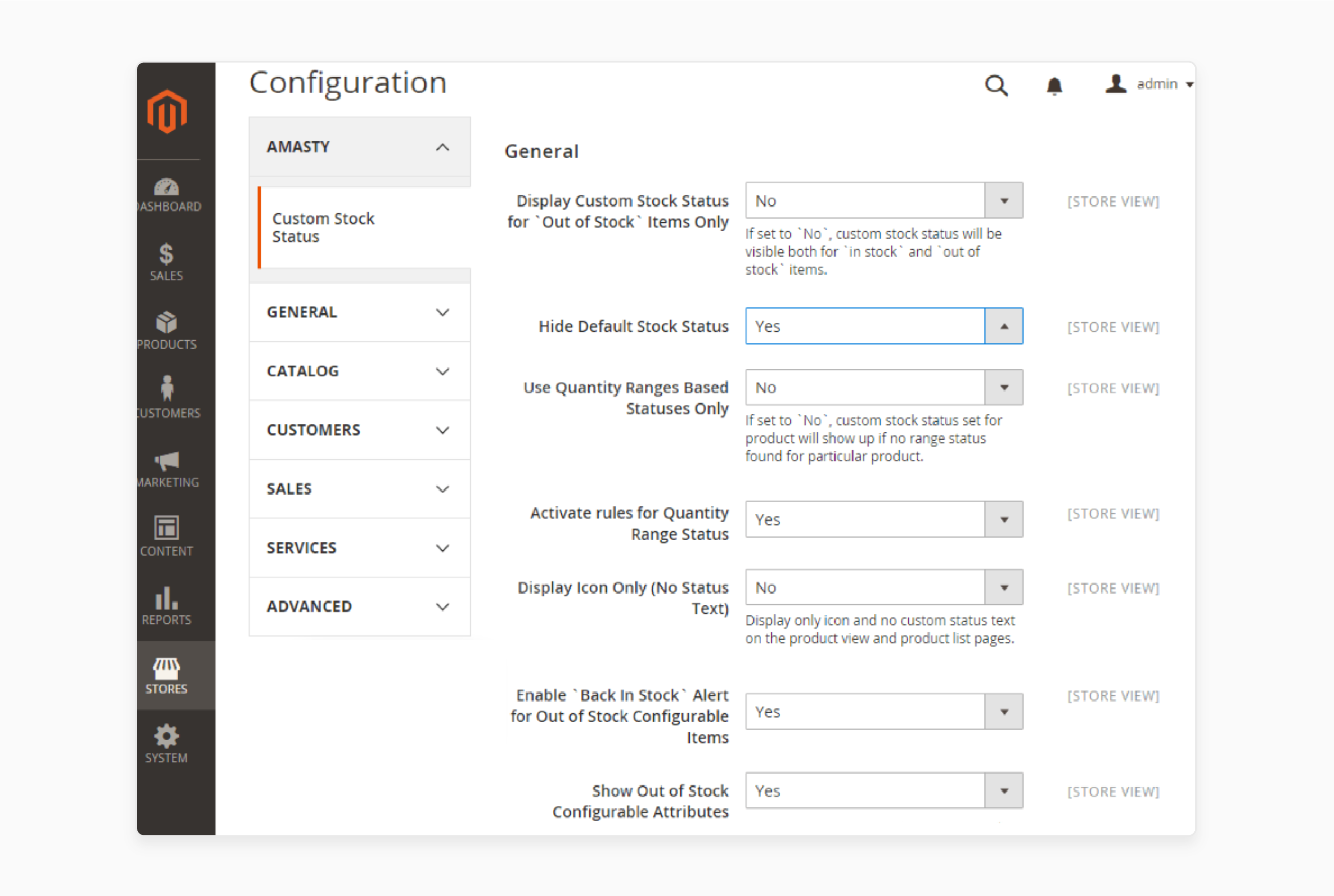

Method 1: Custom Stock Status

The Custom Stock Status extension creates tailored stock statuses for all product types. Key features include:

-

Create unlimited product stock statuses.

-

Use time-based variables (e.g., tomorrow, day-after-tomorrow). It is used to display expected back-in-stock dates.

-

Assign stock statuses to products automatically or manually.

-

Display quantity-based statuses for different product groups.

-

Edit stock statuses for multiple products simultaneously.

-

Show stock statuses on the shopping cart page. It enables you to encourage customers to complete purchases.

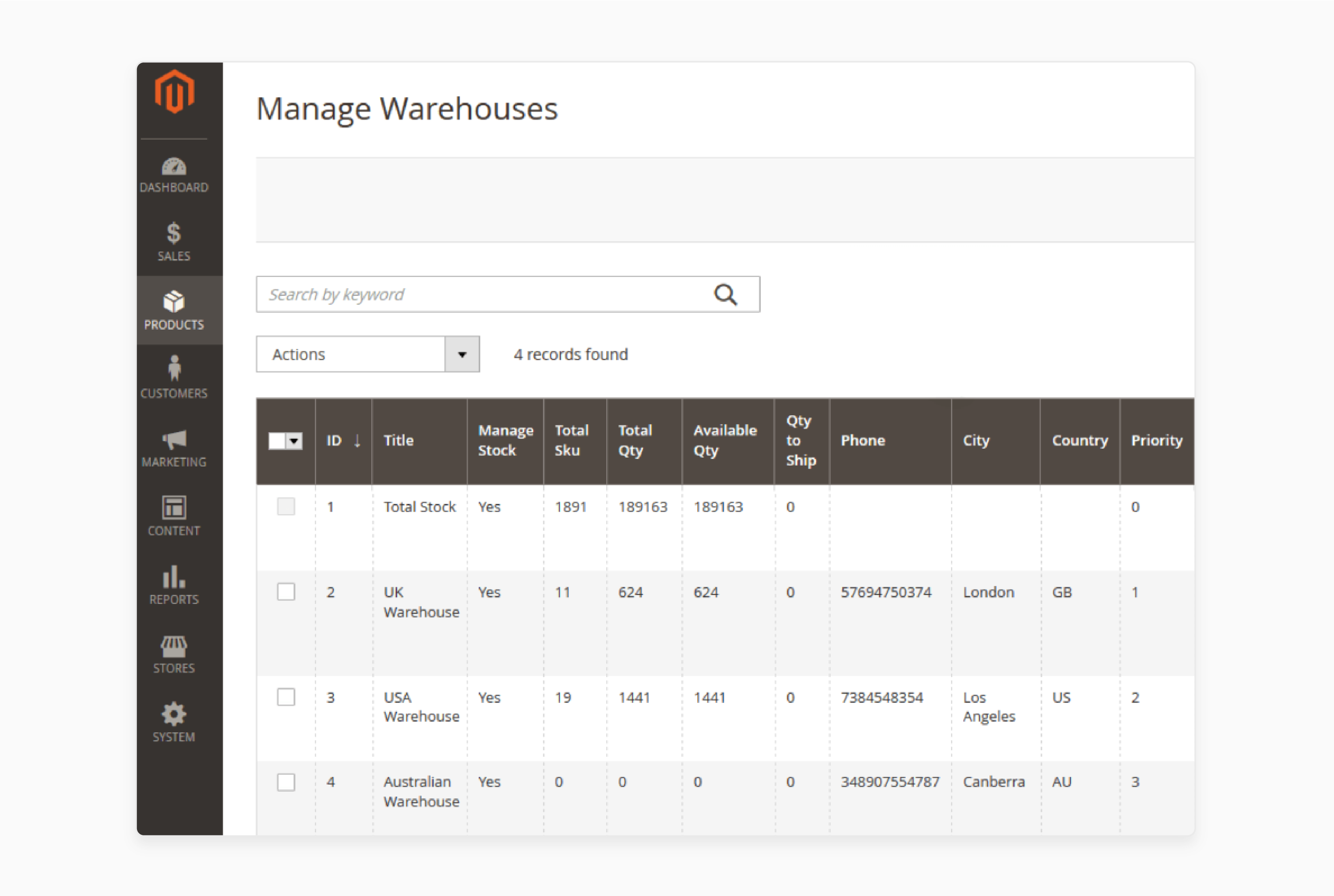

Method 2: Multi-Warehouse Inventory

The Multi-Warehouse Inventory extension simplifies inventory management with multiple warehouses. Key features include:

-

Assign different warehouses to various store views and customer groups.

-

Manage inventory using the advanced stock grid or directly from the product page in the backend.

-

Utilize the 'Manage Warehouses' grid to track inventory across all warehouses.

-

Access three store levels:

i. Stock available for sale

ii. Shipping iii. warehouse management

-

Apply intelligent algorithms to optimize warehouse selection

-

Set shipping costs based on warehouse locations.

-

Automatically hide out-of-stock items.

-

Export stock data manually or automatically.

Dynamic Mechanics For Accurate Inventory Levels

Magento 2’s architecture focuses on managing stock quantities and the Out-of-Stock Threshold. The SourceItemInterface manages stock at the source level. It doesn't address threshold adjustments. Developers can utilize the StockItemInterface and its setMinQty method to adjust the Out-of-Stock Threshold dynamically. It allows for more flexible inventory management.

Implement these changes to disable the useConfigMinQty setting. It ensures Magento doesn't revert to default values. Also, setting negative thresholds allows for backorders, providing further control over inventory levels. These features enhance inventory accuracy and customer satisfaction. However, they weigh the risks of enabling backorders. It allows businesses to avoid stockouts and better meet customer demand.

Setting Up Magento 2 Product Is Out Of Stock Notifications

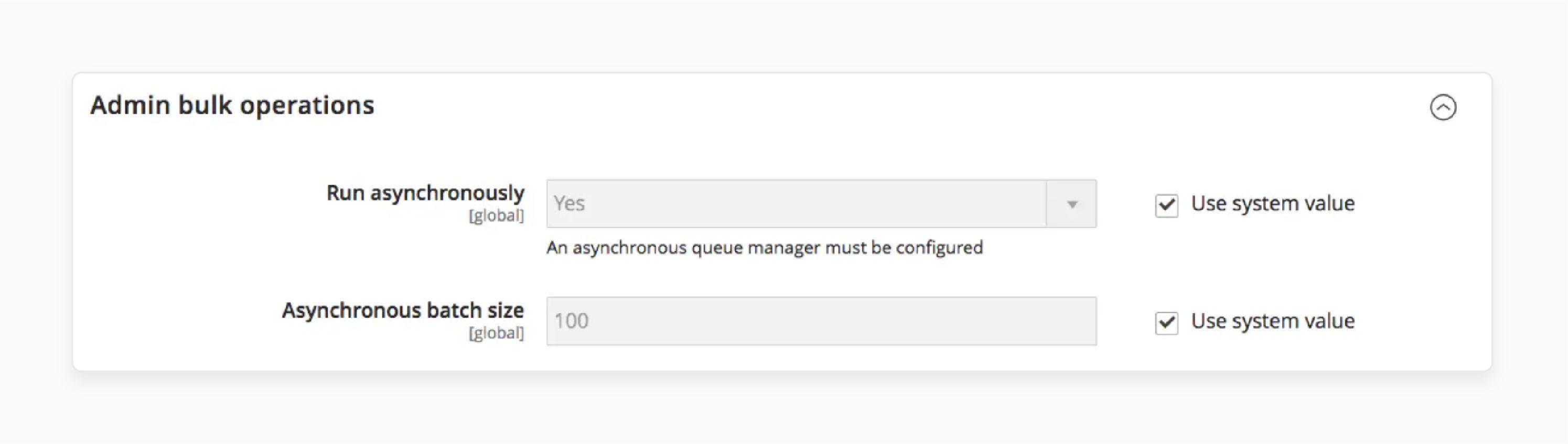

1. Admin Bulk Operations

To configure and support asynchronous queue managers, you must use the command line, which may require developer assistance. Check the below configuration settings:

-

Run asynchronously: It controls whether bulk operations are performed asynchronously. Examples include assigning sources, unassigning sources, and transferring inventory to a source. Bulk actions are collected until they reach the specified batch size & are processed. This feature is disabled by default. Options include:

i. Yes: Runs all bulk operations for inventory management asynchronously. Requires configuring an asynchronous queue manager ii. No: It is the default value. Bulk operations are not run asynchronously.

-

Asynchronous batch size: It allows you to enter a value when 'Run asynchronously' is set to "Yes". The default batch size is "100". It means actions are executed when the number of operations reaches this limit.

2. Inventory Indexer Settings

- Stock/Source reindex strategy: It determines the reindexing strategy for stock/source data. Options include 'Synchronous' and 'Asynchronous'. It requires an asynchronous queue manager.

Note: The inventory indexer is triggered when the product is saved. It is due to the dependency on order-related activities, regardless of the chosen setting.

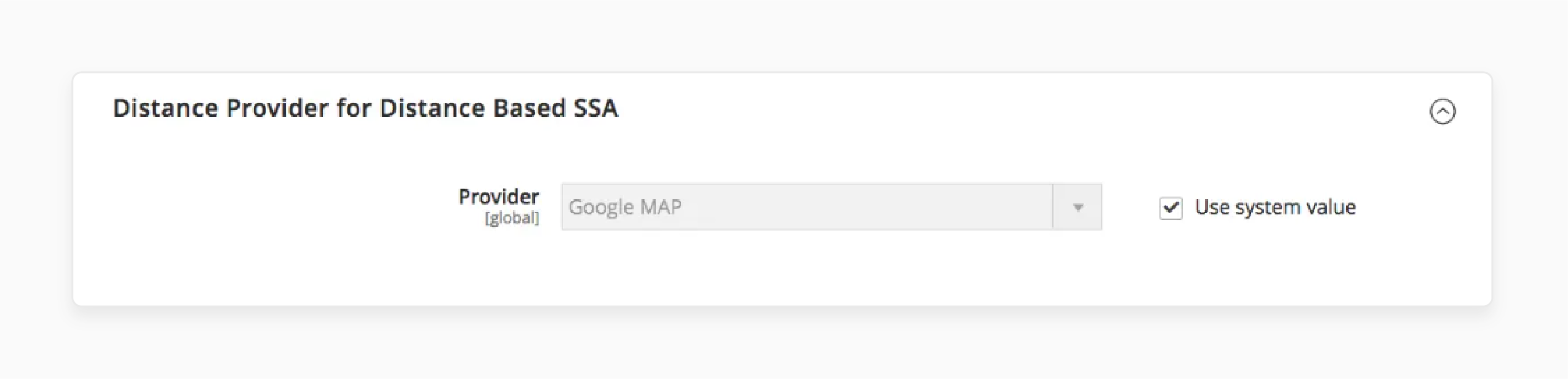

3. Distance Provider for Distance-Based SSA

-

Provider: It selects the provider for the 'Distance Priority Source Selection Algorithm'. This feature is enabled by default. Options include:

i. Google MAP: Google uses services to calculate the distance and time. This calculation is done between the shipping destination and source locations. It requires a Google API key and may incur charges from Google.

ii. Offline Calculation: Uses an embedded database to calculate distances. Developer assistance may be needed to download the location content for all shipping countries.

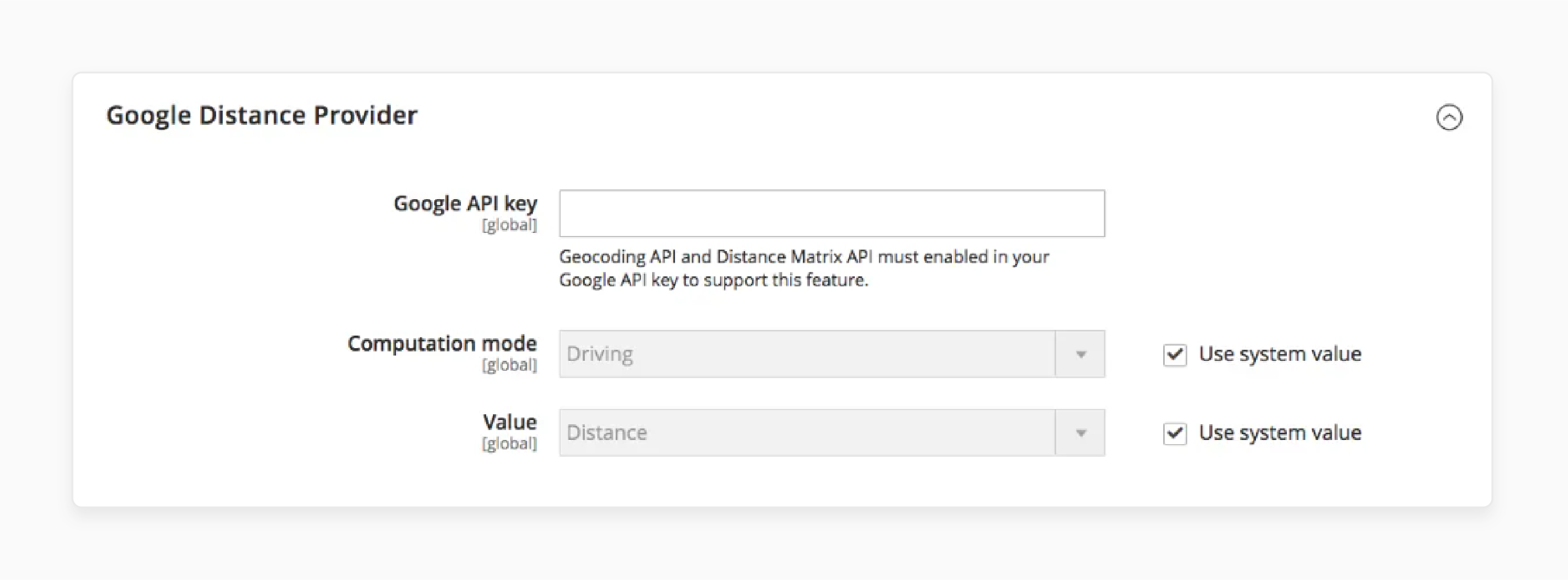

4. Google Distance Provider

-

Google API key: It enters the Google API key for the Google MAP provider. It is obtained from the Google Maps Platform. Ensure the Geocoding API and Distance Matrix API are enabled.

-

Computation mode: It specifies the directions and routes. It uses them to calculate the distance from the shipping address to the source. The default mode is Driving. Options include:

i. Driving: Standard driving directions using road networks. ii. Walking: Uses pedestrian paths and sidewalks. iii. Bicycling: Uses bicycle paths (available in select locations).

-

Value: It determines what is calculated and returned for the source-to-destination distance. The 'Distance Priority Algorithm' recommends the source with the shortest distance or time. Options include:

i. Distance: Returns the distance in kilometers, meters, miles, or feet. ii. Time to Destination: Returns the time to travel from the source to the destination in hours and minutes.

Troubleshooting Common Issues With Stock When Order Is Cancelled

| Issue | Description | Solution |

|---|---|---|

| Stock Not Updated Correctly | After canceling an order, the stock levels don't reflect the correct quantity. | Check the "Set Items' Status to be In Stock When Order is Canceled" setting in the Magento admin panel. Make sure it's configured correctly to update stock levels as needed. |

| Stock Increases Unnecessarily | Stock quantity increases even when it shouldn't after an order is canceled. | Ensure that the "Decrease Stock When Order is Placed" option is set to "Yes" to prevent unnecessary stock increases. |

| Stock Reservations Not Adjusted | Stock reservations remain unchanged after cancellation, affecting salable quantity. | Verify that reservation compensations are correctly entered to adjust salable quantities. It can be managed through Magento's inventory settings. |

| Items Not Returning to Stock | Canceled items don't return to stock, causing discrepancies in inventory. | Confirm that the "Return to Stock" option is enabled for refunds and cancellations in your inventory settings. |

| Incorrect Stock Status Displayed | The product status remains 'Out of Stock' even after cancellation and restocking. | Refresh your cache and reindex your Magento store. It helps to ensure stock status updates are displayed correctly on the storefront. |

| Backorders Affecting Stock Levels | Backorders are still being accepted even after order cancellation, leading to stock issues. | Disable backorders if not needed. Review your backorder settings to align with your inventory strategy. |

FAQs

1. How does the out-of-stock threshold interact with backorders and negative inventory?

When backorders are enabled, and you allow qty below 0, out-of-stock works differently. Products can still be purchased even if the quantity falls below the threshold. The system will track negative inventory until the items in my products are back in stock. This feature is part of Magento 2's core functionality. However, some developers have created custom extensions on GitHub.

2. How does Magento 2's out-of-stock threshold feature impact my e-commerce store?

Using Magento 2, your ecommerce store's inventory management can be affected. When a product's quantity falls below zero, the system's behavior depends on your settings. If backorders are enabled, customers can still place orders. They can do this even when stock is really low or negative. This feature helps maintain sales momentum while alerting you to restock. However, if backorders are disabled, the product will show as unavailable. It potentially impacts your sales but prevents overselling.

3. How can I use the out-of-stock threshold in Magento2 to manage backordered items?

In Magento 2, you can configure your store to accept backorders when the quantity falls below the set threshold. When a product is backordered, the system accepts backorders when the quantity falls below zero. It allows customers to place orders even when items are out of stock. To use it in order to manage backordered items effectively, you can set a negative threshold. It tells the system to treat the product as in stock until it reaches that negative value. It gives you more flexibility in handling backorders while maintaining accurate inventory tracking.

4. How can I manage your Magento inventory to allow customers to place orders even when stock is low?

To manage your Magento store effectively, you can configure the out-of-stock threshold. Go to Stores > Configuration > Catalog > Inventory in your admin panel. Set the "Out-of-Stock Threshold" to a value of "zero" or even a negative number. It allows the system to show that stock is available even when physical inventory is low. As a result, customers can place orders for these items. You can use this feature in order to make more items available for purchase. It potentially increases sales while you work on restocking.

5. How does Magento 2's out-of-stock help manage customer expectations when inventory is low?

Magento 2 gives you the tools to manage inventory effectively, even when stock is running low. When you use these features, the system automatically notifies customers that orders can still be placed for items with "low" or "zero" inventory. For example, setting an appropriate out-of-stock threshold and enabling backorders. This transparency helps maintain customer satisfaction. Also, when a new amount is added to your inventory, the system updates in real time. It ensures that customers always see accurate stock information. By leveraging these features, you can balance inventory management with customer service. They help you to increase sales even when physical stock is temporarily depleted.

6. How does the out-of-stock threshold affect order processing and shipments in Magento 2?

The out-of-stock threshold in Magento 2 impacts how orders are processed and shipped. You can set a threshold in the admin panel and go to configure inventory settings. It enables you to define the maximum number of a product that can be sold before it's marked as out of stock. It doesn't necessarily limit the maximum quantity a customer can order, especially if backorders are enabled. However, it does affect the order's processing status. Orders placed when stock is below the threshold might be put on hold or flagged for special handling. It allows you to manage expectations for shipments to complete orders. It is especially true when you need to wait for restocking before fulfilling the order. You can balance between maintaining available inventory & ensuring timely order processing and shipment.

Summary

The out-of-stock threshold Magento 2 prevents unexpected stock shortages. It helps:

- Enhance customer experience by keeping your product pages updated.

- Streamline stock management and avoid common stock-related issues.

- Ensure customers are informed about product availability, even when stock levels are low.

- Optimize your store's performance and minimize stock issues.

- Maintain accurate stock levels and keep customers informed about product availability.

Determine when products should be marked as out of stock with Magento hosting plans.