4 Steps to Configure Magento 2 Inventory Reservation

Are you struggling to keep your inventory in sync? Magento 2 Inventory Reservation uses a reservation system to manage stock until shipment. This approach ensures accurate stock levels across all sales channels.

This tutorial will cover how to set up Magento 2 for better stock allocation.

Key Takeaways

-

What are the aspects of inventory settings?

-

Find the parts that keep stock allocation working smoothly.

-

Follow simple steps to configure stock settings.

-

Use methods for handling order cancellations and refunds.

-

Steps to manage partial shipments and adjustments.

-

Find solutions for common issues and insights into future improvements.

-

5 Steps to Manage Partial Shipments with Magento Inventory Reservation

-

Troubleshooting Common Inventory Processed Reservation Issues

What is Magento 2 Inventory Reservation?

Magento 2 Inventory Reservation is a smart system that manages inventory holds. It tracks salable quantities across your eCommerce platform.

Magento 2 inventory reservation prevents overselling by keeping available inventory accurate. It only adjusts stock when items ship. Primary allocations are made for each order. Through reservation calculations and reservation adjustments, it manages stock precisely across sources. This ensures availability for customers while only adjusting actual stock at shipment.

6 Key Components of Inventory Reservation Management

1. Reservation Records

When an order is placed, Magento creates a reservation object. It holds the stock amount for the order. This object includes critical data such as:

-

The SKU

-

Reserved quantity

-

Order status.

Magento tracks allocation using a reservation table. This ensures outstanding reservations are separate from actual stock. It helps to prevent overselling until shipment.

2. Salable Quantity vs. Stock Quantity

Adobe manages two types of quantities. It includes:

-

Salable quantity (available for sale)

-

Stock quantity (actual physical stock).

Allocation reduces only the current inventory salable quantity, not the actual stock. Through compensation reservations, it adjusts for incomplete orders. It keeps the inventory accurate until items ship.

3. Reservation Lifecycle

The reservation process follows items from order to shipment or cancellation. It keeps reservations in the scope until they’re complete. By following the sum of all reservations, Adobe ensures every order is managed correctly. Reservations are append-only operations. It tracks changes without directly changing stock, avoiding overlapping updates and errors.

4. Multi-Source Inventory (MSI)

For companies with multiple warehouses. The distributed inventory tracks stock levels per source. For example, the Baltimore source has 20 units, and the Reno source has 10. Each source inventory links to stock and uses a source selection algorithm. The reservations help to pick the best warehouse for each order. This setup keeps inventory levels accurate across locations and prevents reservation discrepancies.

5. Reservation Compensations

When orders are canceled or partially filled, compensation reservations adjust reserved quantities. Unshipped items return to salable inventory. Allocation adjustments keep stock levels accurate. It adjusts in real-time without manual updates, which helps avoid reservation discrepancies.

6. Reservation Calculations and Automation

Adobe manages reservation adjustments for inventory changes automatically. The inventory management CLI reference allows batch updates. They help to clear these holds on reservations. Automation ensures that allocation adjusts smoothly without manual intervention, keeping inventory data consistent.

4 Steps to Configure General Inventory Settings in Magento

Step 1: Access General Inventory Settings

-

In the Admin Panel, go to Stores > Configuration under the Settings section.

-

Expand the Catalog tab and select Inventory.

-

Find Stock Options and Product Stock Options. Expand these sections to begin configuring inventory management.

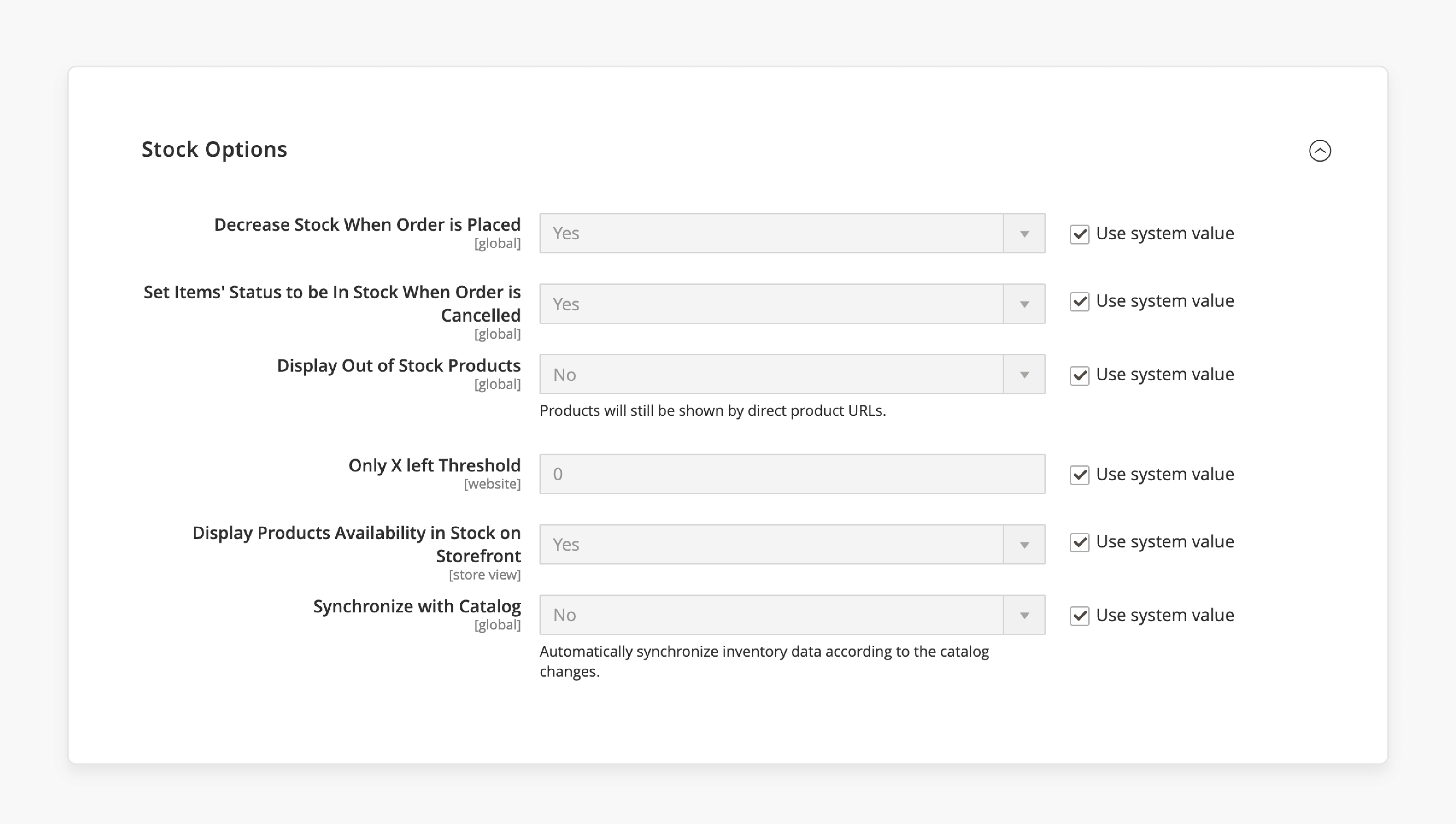

Step 2: Configure Stock Options

-

Open the Stock Options menu to manage global inventory settings.

-

Set Items’ Status to In Stock When Order is Cancelled: Choose Yes to return canceled orders to inventory. It keeps the allocation place holds on inventory accurate.

-

Decrease Stock When Order is Placed: Select Yes to reduce inventory quantities automatically. It is done when an order is placed.

-

Display Out of Stock Products: Choose Yes to show out-of-stock items on catalog pages. Enable Product Alerts to notify customers when out-of-stock items are restocked.

-

Only X Left Threshold: Enter a number to set a low-stock threshold. It triggers an “Only X Items Left” message on product pages. Replace X with the quantity you choose. You can set this per item.

-

Display Products Availability In Stock on Storefront: Select Yes to show “In Stock” or “Out of Stock." It makes it clear to customers when inventory is available.

-

Use System Values: Tick the Use system value boxes to apply default settings.

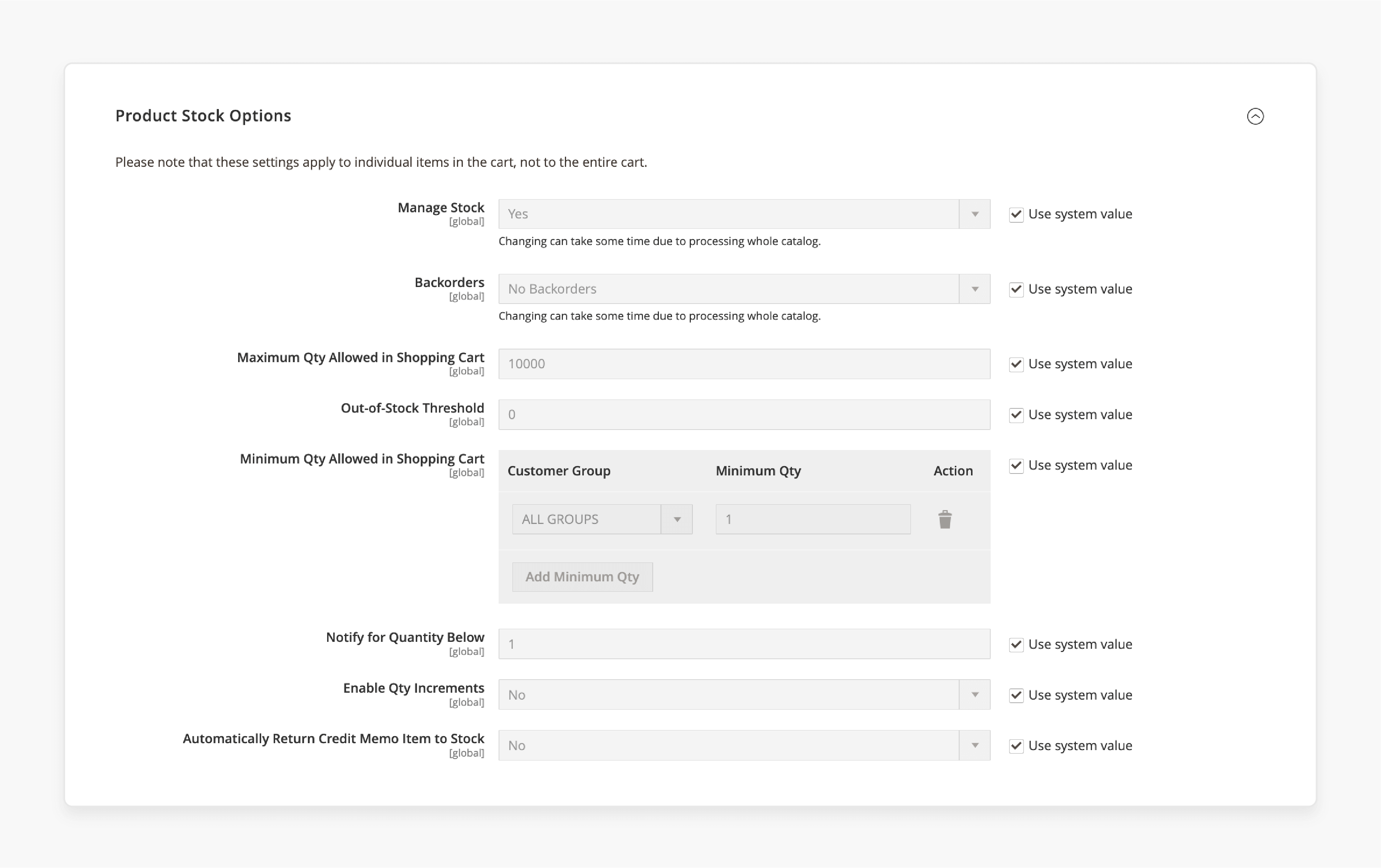

Step 3: Configure Product Stock Options

-

In the Inventory menu under Catalogue. Expand Product Stock Options to set inventory settings per stock on a product level.

-

Manage Stock: Choose Yes to enable stock management. Disable this for virtual or downloadable items if needed.

-

Backorders: Select a backorder option:

-

No Backorders: Backorders for out-of-stock items are not allowed.

-

Allow Qty Below 0: Allows customers to place backorders even if stock is below zero.

-

Allow Qty Below 0 and Notify Customer: Allows backorders and notifies customers.

-

-

Maximum Qty Allowed in Shopping Cart: Enter the maximum number of items each customer can add to their cart.

-

Out of Stock Threshold: Set the threshold. It shows an “Out of Stock” message when the stock reaches this level.

-

Minimum Qty Allowed in Shopping Cart: Set the minimum quantity. It is set for items in the cart and chooses the Customer Group it applies to:

-

ALL GROUPS: Applies to all customer groups.

-

NOT LOGGED IN: Applies to guest users.

-

General, Wholesale, Retailer: Applies to specific customer groups.

-

-

Notify for Quantity Below: Enter the stock level. It triggers an “Out of Stock” notification when items are low.

-

Enable Qty Increments: Select Yes to allow quantity increments. After that, set the increment size in Qty Increments.

-

Automatically Return Credit Memo Item to Stock: Choose Yes to restock items. It is done for the items that are refunded. It also ensures that compensated reservation sequences remain updated.

-

Use System Values: Tick the Use system value boxes to apply default settings.

Step 4: Save Configurations

Click Save Config at the top of the Configuration panel to save your settings.

Managing Inventory Reservations During Order Cancellations

1. Automatic Reversal of Initial Reservation

When an order is canceled, Magento 2 inventory management creates a compensation reservation. It offset the primary reservation that deducts stock when the order was placed. This compensation allocation restores the salable quantity. It adds the reserved items back to the available inventory. The process ensures the initial reservation enters the system accurately. It reflects the correct stock. This approach prevents overselling and keeps stock information consistent across channels.

2. Using CLI Commands to Detect and Manage Inconsistencies

Sometimes, incorrect reservations may still occur due to configuration changes or updates. It includes using 2.3.x with manage stock enabled or changing stock configuration and some orders settings. It offers specific CLI commands to identify and correct reservation errors. Running these commands helps resolve reservation inconsistencies. It aligns salable and physical stock quantities and removes outdated or duplicate allocations.

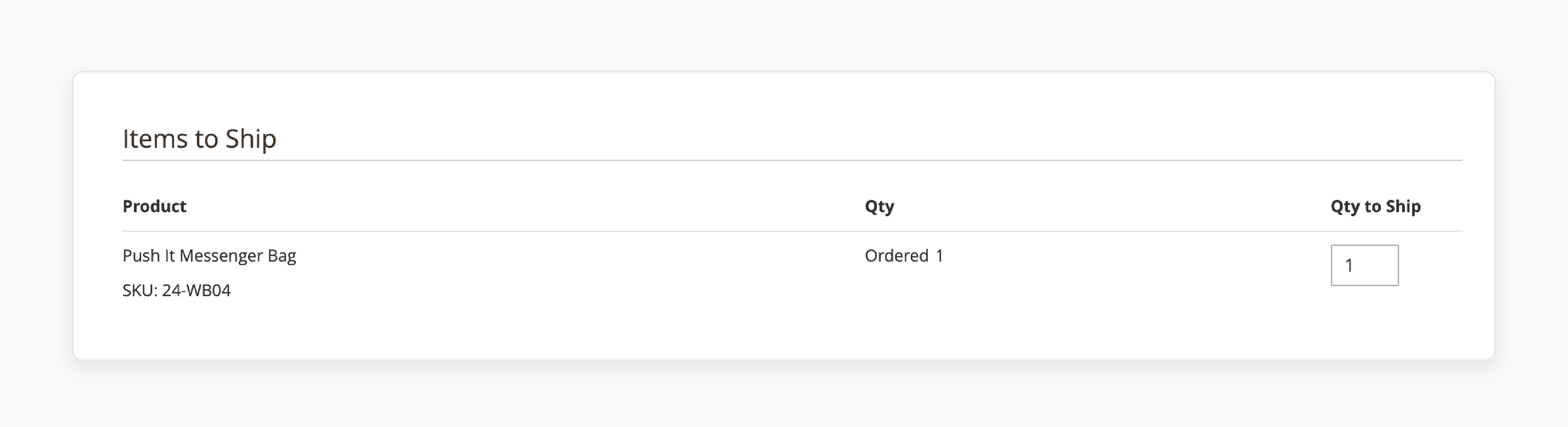

5 Steps to Manage Partial Shipments with Magento Inventory Reservation

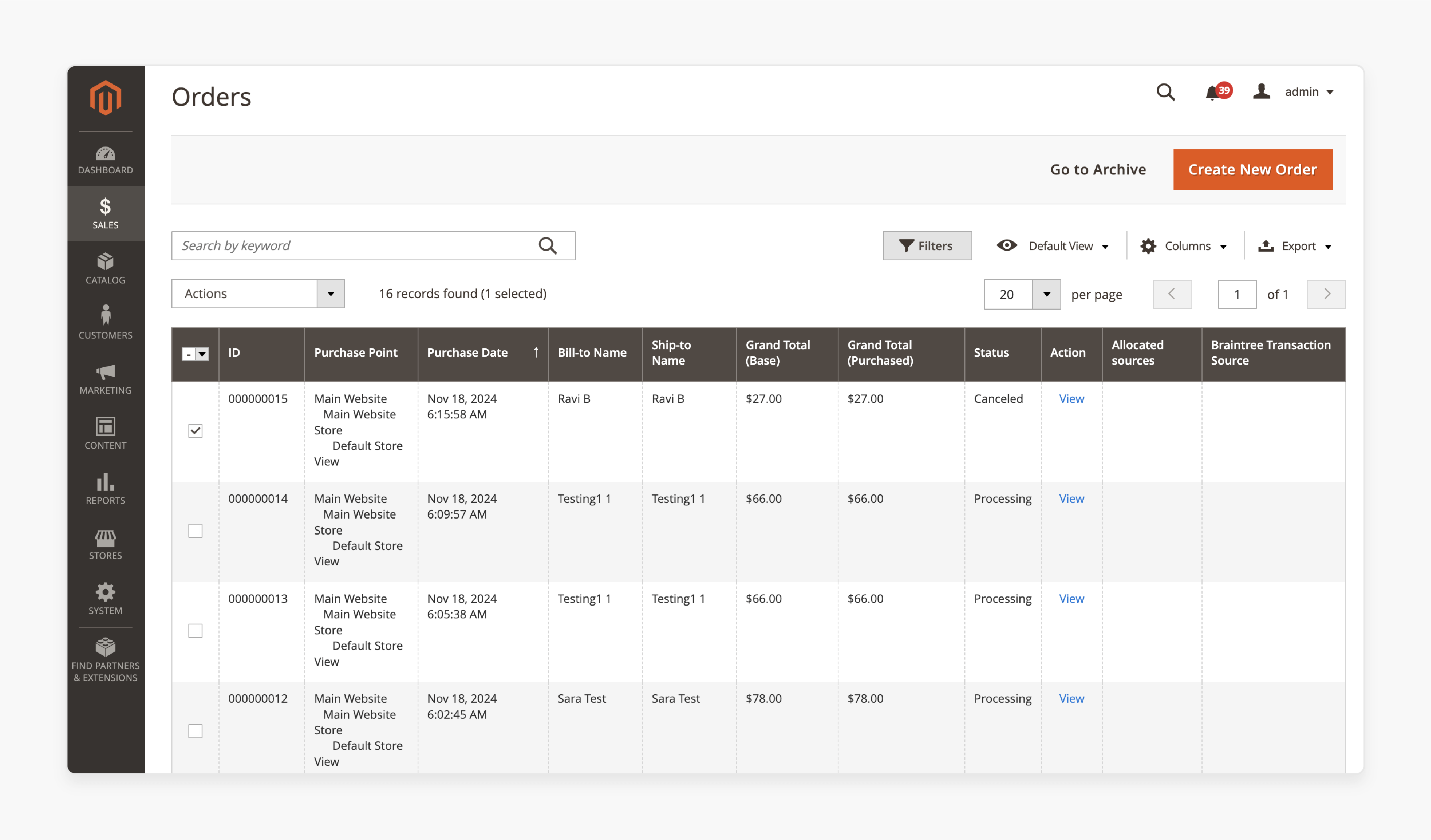

Step 1: Access the Order

In the Magento Admin, go to Sales > Orders and select the order.

Step 2: Start Shipment

Click Ship to begin the partial shipment.

Step 3: Adjust Quantities

In the shipment form, set the quantity and reservations for each item you plan to ship now. For items not included, set their quantities to zero.

Step 4: Select Inventory Source

If using a distributed inventory, choose the source(s) for shipping. Use the source selection algorithm and reservations to pick the best source.

Step 5: Submit Partial Shipment

Review the details, then click Submit Shipment to finish the partial shipment. This lets you fulfill part of an order as stock becomes available.

Stock Allocation Adjustments:

Inventory management provides automatic allocation updates during partial shipments:

-

Reservation Creation: Magento creates an allocation to hold stock for ordered items. This lowers the salable quantity in real-time.

-

Reservation Release: When processing partial shipments, subsequent reservations created. It releases the reserved quantities for shipped items. Allocation keeps the quantity and reservations accurate.

Using Inventory Reservation for Simple and Complex Orders

1. For simple orders:

-

When a customer places an order, Magento Open Source checks the salable quantity.

-

If stock is available, it orders reservations to hold the amount.

-

Upon shipping, reservations are automatically cleared. The actual stock amount is reduced to match what was shipped.

-

If the order is canceled before shipping. Adobe releases the allocation, returning the held quantity to the salable stock.

2. For complex orders (e.g., multi-address orders):

-

Reservations for these orders are created for each shipping destination address and source.

-

Adobe treats each address in a separate order. It is an individual allocation for each location. This setup allows each part of the order to be shipped separately.

-

As each shipment is processed. The related allocation clears, and the stock is updated accordingly.

-

In partial shipments, only the allocation for shipped items is cleared. The allocation for the remaining items stays active until they are shipped.

3. For refunds:

Magento lets you return the product inventory to stock, updating inventory levels accurately.

4. In cases of Reservation Discrepancies:

-

CLI commands detect and handle issues. It includes inventory management loses the initial reservation. This enters too many reservation compensations.

-

These commands help keep stock levels accurate by resolving any inconsistencies.

Troubleshooting Common Inventory Processed Reservation Issues

| Issue | Details |

|---|---|

| Reservation Inconsistencies | The allocation quantity does not match the actual inventory. It can lead to overselling or underselling. |

| Incorrect Reservations on MSI | Alowcations may apply wrongfully across destination address and source locations. It creates stock discrepancies in a multi-source inventory setup. |

| Stuck Reservations after Order Cancellation | Canceled orders may still place holds on inventory quantities, reducing salable stock incorrectly. |

| Outdated Inventory after Bulk Actions | Bulk actions can cause allocation mismatches if not processed correctly. It includes imports or mass updates. |

| Double Reservations on Partial Shipments | For partial shipments, reservation enters for the initial stock and may duplicate. It causes incorrect stock levels. |

| Reservation Quantity Display Errors | The displayed allocation quantity needs to be appropriately updated. This leads to inaccurate stock information for customers. |

| Compensation Reservations Not Applied | When orders are canceled or refunded, it may not issue a reservation in response. It can cause an overestimated stock level. |

FAQs

1. How does Adobe Commerce handle reservations at order placement?

In Adobe Commerce, when an order is placed. The system creates primary allocation to hold the ordered stock. This reduces the salable quantity across all sources. By placing allocation at order placement, Adobe prevents overselling. It keeps the inventory accurate for each order.

2. What is the role of the source priority algorithm in inventory management?

The source priority algorithm decides which source fulfills an order. It can be based on priorities and links sources to stock in order. Reserving the items from high-priority sources first supports efficient inventory management. It is done by automating source selection for items to fulfill the order.

3. How does Magento manage the complete reservation sequences for multi-source inventory?

Magento manages distributed inventory by creating complete allocation sequences. Alowcations produced in a single transaction ensure accurate allocation across sources as needed. It keeps accurate stock levels across warehouses and locations.

4. How does Magento 2 detect and manage allocation inconsistencies?

Inventory management detects and manages allocation inconsistencies. It can be done using tools that compare reserved quantities with actual stock. It checks order status and allocation for mismatches. It keeps the stock records accurate. If an inconsistency exists, it provides options to resolve it.

5. How does Magento handle the response to a new order with inventory reservations?

When a new order is placed, Adobe creates a primary allocation and enters it into the system. This adjusts stock for a website. It holds the items to fulfill the order while keeping physical stock unchanged.

6. How does Magento clear the reservation if an order is canceled?

If an order is canceled, Magento clears the allocation for that order. This action frees the reserved stock and returns it to the in-stock inventory. It also adjusts the salable quantity. Clearing allocation for canceled orders ensures inventory reflects real-time availability.

Summary

Magento 2 Inventory Reservation manages stock. It creates the initial allocation produced for each order. This ensures accurate tracking of available quantities. It totals all the initial reservations across sources, linking sources to stock accurately.

Consider the following while managing:

-

Reservation Objects: Helps Magento checks prevent overselling until shipment.

-

Reservation Lifecycle: Manages stock across sources smoothly.

-

Multi-Source Inventory (MSI): Manages inventory per source.

-

Reservation Adjustments: Keeps stock accurate and avoids reservation is 0 without any errors.

Explore Magento hosting plans for inventory reservations and optimize stock management.